Metal Stamping (forming) is the process of placing flat sheet metal in either blank or coil form, into a stamping press where a tool and die surface forms the metal into a net shape. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials. Metal stamping can include a number of metal forming processes; blanking, punching, bending, and piercing and more.

Blanking: This process is about cutting the rough outline or shape of the product. This stage is about minimizing and avoiding burrs, which can drive up the cost of your part and extend lead time. The step is where you determine hole diameter, geometry/taper, the spacing between edge-to-hole and insert the first piercing.

Bending: When you are designing the bends into your stamped metal part, it is important to allow for enough material — make sure to design your part and its blank so that there is enough material to perform the bend. Some important factors to remember:

- If a bend is made too close to the hole, it can become deformed.

- Notches and tabs, as well as slots, should be designed with widths that are at least 1.5x the thickness of the material. If made any smaller, they can be difficult to create due to the force exerted on punches, causing them to break.

- Every corner in your blank design should have a radius that is at least half of the material thickness.

- To minimize instances and severity of burrs, avoid sharp corners and complex cutouts when possible. When such factors cannot be avoided, be sure to note burr direction in your design so they can be taken into account during stamping

Coining: This action is when the edges of a stamped metal part are struck to flatten or break the burr; this can create a much smoother edge in the coined area of the part geometry; this can also add additional strength to localized areas of the part and this can be utilized to avoid secondary process like deburring and grinding. Some important factors to remember:

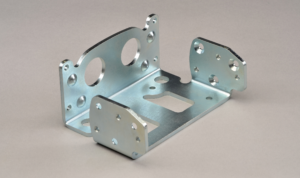

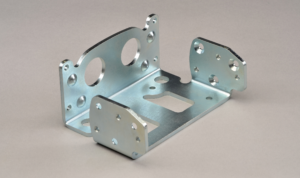

Examples of Stamped Parts:

- Industries We Serve; Components, Parts and Services We Provide – CLICK HERE

- Aircraft Component Parts and Supplies

- Automotive Component Parts Fasteners and Supplies

- Biotech Machined Components Parts and Fasteners

- Construction Fasteners, Supplies and Tools

- Defense & Military Fasteners, Hardware and Machined Component Parts

- Electrical Connectors, Insulators, Lugs, Terminal Blocks, Assorted Supplies

- Electronic Component Parts and Supplies

- Firearms Machined Components Parts and Fasteners

- Food & Beverage Fasteners, Machined Component Parts, Fasteners and Supplies

- Medical Machined Components Parts, Fasteners and Supplies

- Oil Field and Energy Components Parts and Fasteners and Supplies

- Water Filtration and Distribution Injection Molding, Machined Components, Fasteners and Supplies

PLEASE CALL US FOR QUESTIONS OR A QUOTE: (916) 202-1104 TOLL FREE FAX LINE: (866) 265-0011 or Email Us